How does a fiber laser machine work

The components as well the FM-Desktop fiber laser are covered by a 30-day guarantee and a 2-year parts and labor warranty.

The laser beam is then projected onto the work materials using focus lenses.

Power

An affordable entry-level fiber laser cutter costs from $15,800 to $32,800 with lower laser powers of 1000W and 1500W for beginners with hobbyists, the top rated automatic fiber laser cutting system cost starts from $29,800 with medium laser powers of 2000W, 3000W, 4000W, and 6000W for precision cutting in in commercial use. The best high speed industrial fiber laser cutting machines are priced from $88,000 to $500,000+ with higher laser powers of 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W for thick metal fabrication in professional use. The best budget fiber & CO2 combo laser cutting machine costs from $19,800 for multipurpose to cut metal, wood, MDF, plywood, acrylic, plastic, fabric, leather.

GSS Machinery also provides auto-loading and unloading systems that can be integrated with fiber laser machines for maximum automation, increasing speed and efficiency for your processing requirements.

Gulf States Saw & Machine Co. has an EZCAD2.0 control software that works with their FM1212-50S laser engraver.

Fiber lasers use much less energy than CO2 lasers. They operate at shorter wavelengths (780 nm to 2200 nm) and have a much higher absorption.

The components as well the FM-Desktop fiber laser are covered by a 30-day guarantee and a 2-year parts and labor warranty.

The laser beam is then projected onto the work materials using focus lenses.

With the addition of a galvo head, they can also work at a very high speed. Galvo heads are typically used in portable laser engravers.

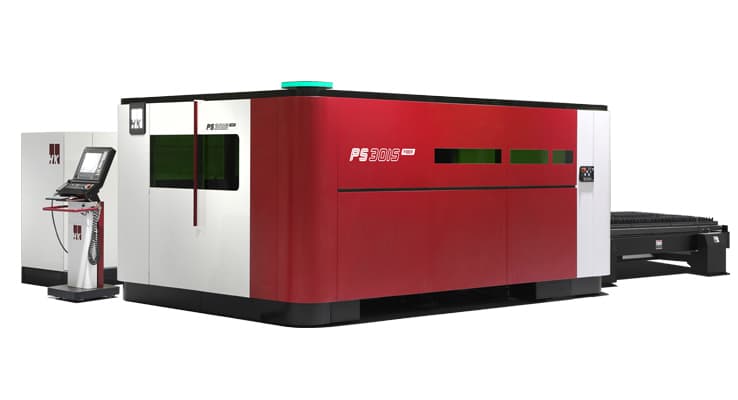

It can be used for flatbed cutting and bevel cutting, and the edges are neat and smooth. It is suitable for precision cutting of sheet metals. In addition, the robotic arm can do 3D cutting instead of the 5 axis laser cutter. Compared with CO2 laser cutters, fiber laser cutters will save space and gas consumption, and has a high photoelectric conversion rate. It is a new power tool of energy saving and environmental protection, and it is also one of the world's leading technological CNC machine tools. 1. High accuracy: The laser positioning accuracy is 0.05mm, and the repeated positioning accuracy is 0.03mm, 2. Narrow slit: The laser beam is focused into a small spot, so that the focus reaches a high power density, the material is rapidly heated to the point of vaporization, and the holes are vaporized. With the relative linear motion of the light beam and the material, the hole continuously forms a narrow slit, and the width of the slit is generally 0.10-0.20mm, 3. Smooth cutting edge: There is no burr on the cutting edge, and the roughness of the cutting surface is generally controlled within Ra6.5., 4. High speed: The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than other metal cutting tools., 5. High quality: It is a non-contact cutting, which endures little thermal influence, the part basically has no thermal deformation, and completely avoids the slump formed when the material is punched and sheared., 6. Non-destructive cutting: The laser cutting head does not come into contact with the surface of the substrate, ensuring that the parts are not scratched., 7. Good flexibility: Laser has good flexibility to cut any graphics, including metal pipes and other shaped metals, 8. Save mold investment: Laser cutting requires no mold, no mold consumption, no mold repair, saving mold replacement time, thereby saving processing costs and reducing production costs, especially suitable for processing large projects, 9. Material saving: With CNC programming, the parts of different shapes can be cut to maximize the utilization rate of materials., 10. Easy to use: Using CAD software to design graphics, using CAM software to model and output laser cutting files, using CNC controller to drive the machine to achieve automatic metal cutting, 11. Safety and environmental protection: Less waste, low noise, clean, safe and pollution-free, greatly improving the working environment.

We offer a variety of laser power options, including 1000W, 1500W. 2000W. 2500W. 3000W. The fiber laser machines have a cutting speed up to 35 m/min. This allows them to complete jobs quickly and with high precision. Laguna Tools also offers machines with enclosed areas that eliminate light pollution.

To expand the engraving area, longer focal length lenses can be used. These lenses require high concentrated power and are taller.

Fiber lasers are very popular in engraving applications. They have wavelengths ranging from 780nm up to 2200nm.

It simply means that, when working in materials such as metals that reflect laser light, they absorb fiber light at a much greater rate than the laser light generated from CO2 lasers.

You can access the software interface simply by entering your machine's IP address in browser's address field.

This fiber laser can provide a repeatable precision up to +-0.0001" and a beam strength of less than 1 M2.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Thin carbon fiber mat can be cut with some fraying - but not when coated. The laser can cut or etch. The laser can cut materials such as wood, paper, cork, and some plastics.